Don't hesitate to send a message

-

Fire hoses and nozzles represent the primary tools in a firefighter's arsenal, serving as the critical link between water supply and fire suppression. Understanding the various types, constructions, a...

READ MORE -

Fire hose couplings are critical components in firefighting equipment, serving as connectors between hoses, nozzles, hydrants, and pumps. They enable quick attachment and detachment while maintaining ...

READ MORE -

From January 12th to 14th, 2026, Taizhou Shenlong Fire Science and Technology Co., Ltd. will proudly participate in the INTERSEC DUBAI 2026 exhibition at the Dubai World Trade Centre.At the exhibitio...

READ MORE -

Fire hose couplings are critical components in firefighting systems, allowing for quick and secure connection between hoses, pumps, and nozzles. These couplings ensure the efficient flow of water or f...

READ MORE

Industrial Fire Hose Couplings: Ensuring Safety and Performance in High-Risk Environments

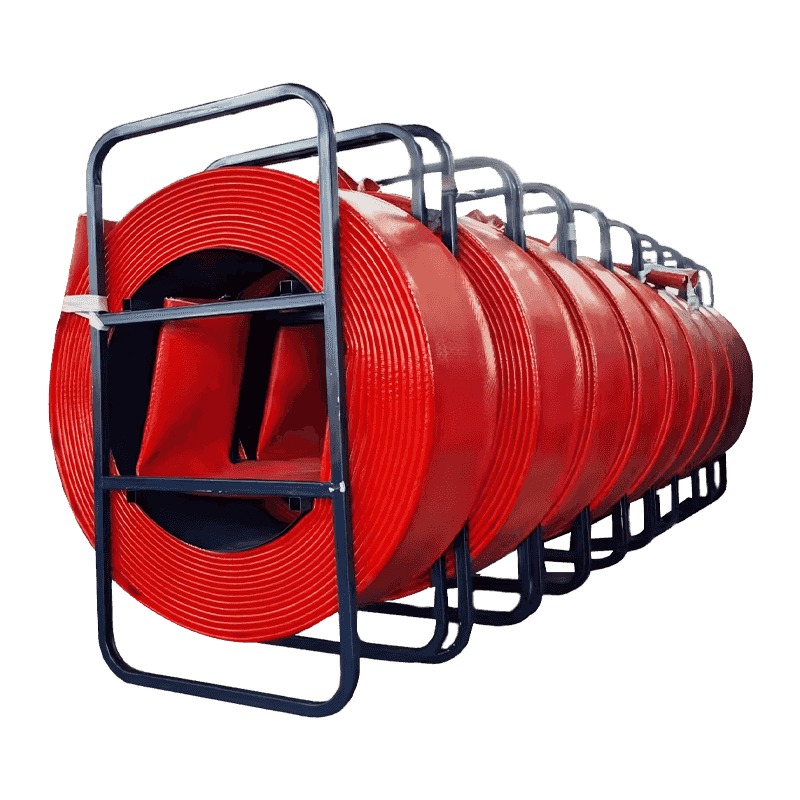

The coupling is the component that connects the hose to the hydrant, pump, or nozzle, and it is critical that these connections are both secure and durable. A well-designed coupling allows firefighters to quickly deploy and disconnect hoses without compromising the flow of water or retardant, especially in high-pressure situations. Whether you’re using an industrial fire hose in a factory, an oil refinery, or a construction site, the quality and functionality of the coupling can make all the difference in an emergency.

Most industrial fire hoses are fitted with couplings made from durable metals like brass or aluminum. These materials are chosen for their resistance to corrosion, strength, and ability to handle the extreme pressures associated with firefighting operations. Brass couplings, in particular, are known for their longevity and reliability, making them a popular choice for industries that require long-lasting fire safety equipment. Aluminum couplings, while slightly lighter, offer similar strength and are often chosen for situations where reducing weight is a priority. The choice between brass and aluminum couplings depends largely on the specific needs of the facility and the type of industrial fire hose being used.

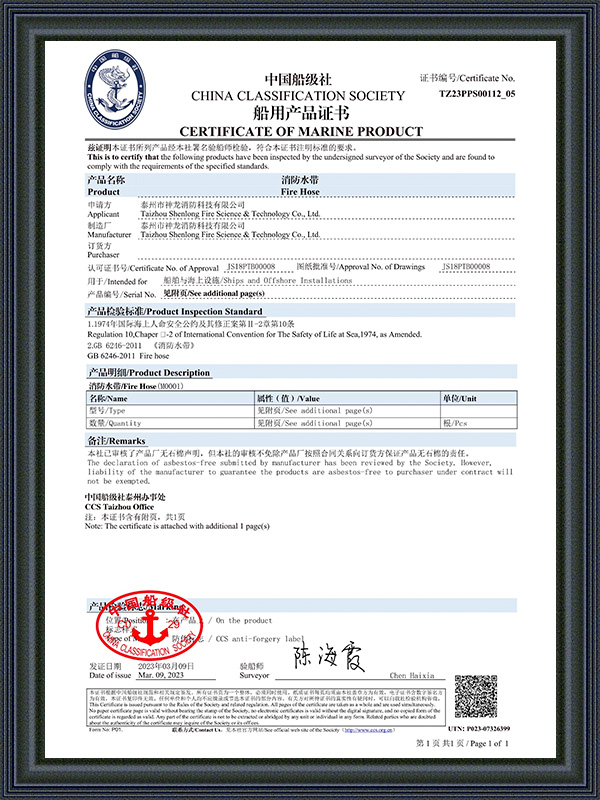

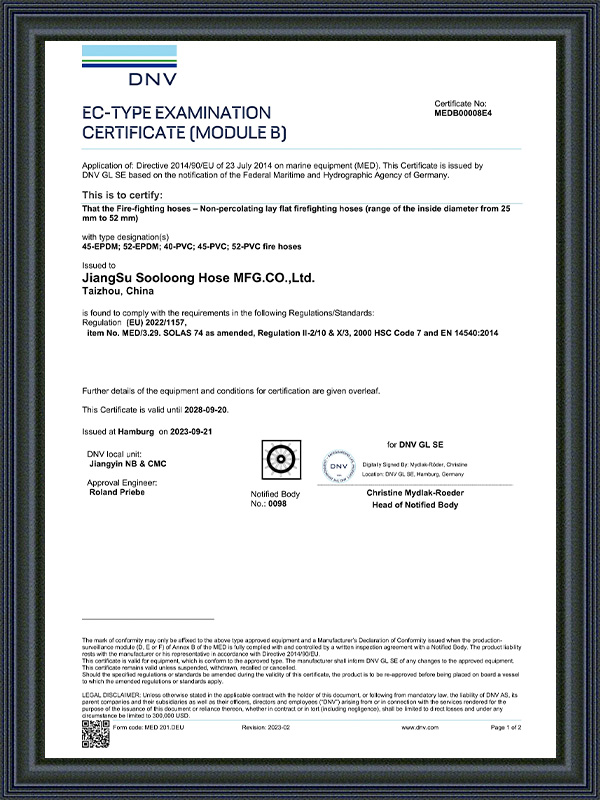

Industrial hose couplings must meet stringent safety standards to ensure they can withstand the intense pressures often exceeding 300 psi. A poorly constructed coupling can lead to leaks or even complete disconnections, posing serious risks in critical firefighting situations. This is why it’s essential that the couplings used in your industrial fire hoses are tested to meet or exceed industry regulations. Compliance with these standards ensures that the couplings will function correctly under pressure, allowing the hose to perform optimally when it’s needed most. It’s important for businesses to select industrial fire hoses from manufacturers who prioritize quality assurance and safety testing to meet these rigorous requirements.

In addition to the material and pressure resistance, the design of the coupling itself is key to ensuring ease of use during emergencies. The coupling should be simple to connect and disconnect, even in high-stress environments. Many modern industrial fire hose couplings are designed with ergonomic features, such as easy-grip handles or locking mechanisms that prevent accidental disconnections during use. A quick-connect coupling system can drastically reduce the time needed to deploy the hose, which is especially critical in industries where every second counts during a fire emergency.

Regular maintenance and inspection of industrial fire hose couplings are equally important to ensure their continued functionality. Over time, couplings can experience wear from frequent use, exposure to harsh chemicals, or the physical stresses of handling. To avoid issues such as leaks or difficulty in coupling, it’s important to inspect these components regularly and replace them when necessary. This simple step in the maintenance process can significantly prolong the lifespan of your industrial fire hoses and improve the overall reliability of your fire protection system.

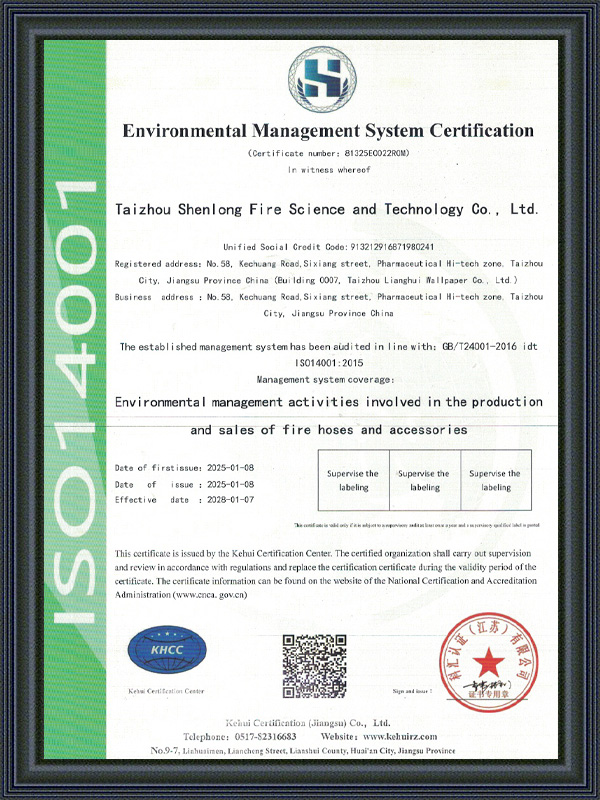

When choosing industrial hoses, it’s essential to consider the type of couplings used and their compatibility with your existing firefighting infrastructure. Whether you are outfitting a new facility or upgrading your fire safety equipment, the right coupling system can enhance the efficiency and safety of your firefighting efforts. At Shenlong, we understand the critical role couplings play in industrial fire hose performance, and we manufacture products that prioritize durability, ease of use, and long-term reliability, ensuring your fire safety equipment will always be ready when you need it most.

English

English русский

русский Español

Español Deutsch

Deutsch عربى

عربى Français

Français Português

Português