Don't hesitate to send a message

-

Fire hoses and nozzles represent the primary tools in a firefighter's arsenal, serving as the critical link between water supply and fire suppression. Understanding the various types, constructions, a...

READ MORE -

Fire hose couplings are critical components in firefighting equipment, serving as connectors between hoses, nozzles, hydrants, and pumps. They enable quick attachment and detachment while maintaining ...

READ MORE -

From January 12th to 14th, 2026, Taizhou Shenlong Fire Science and Technology Co., Ltd. will proudly participate in the INTERSEC DUBAI 2026 exhibition at the Dubai World Trade Centre.At the exhibitio...

READ MORE -

Fire hose couplings are critical components in firefighting systems, allowing for quick and secure connection between hoses, pumps, and nozzles. These couplings ensure the efficient flow of water or f...

READ MORE

Why TPU is the Material of Choice for Fracturing Hoses: Durability and Performance in Challenging Environments

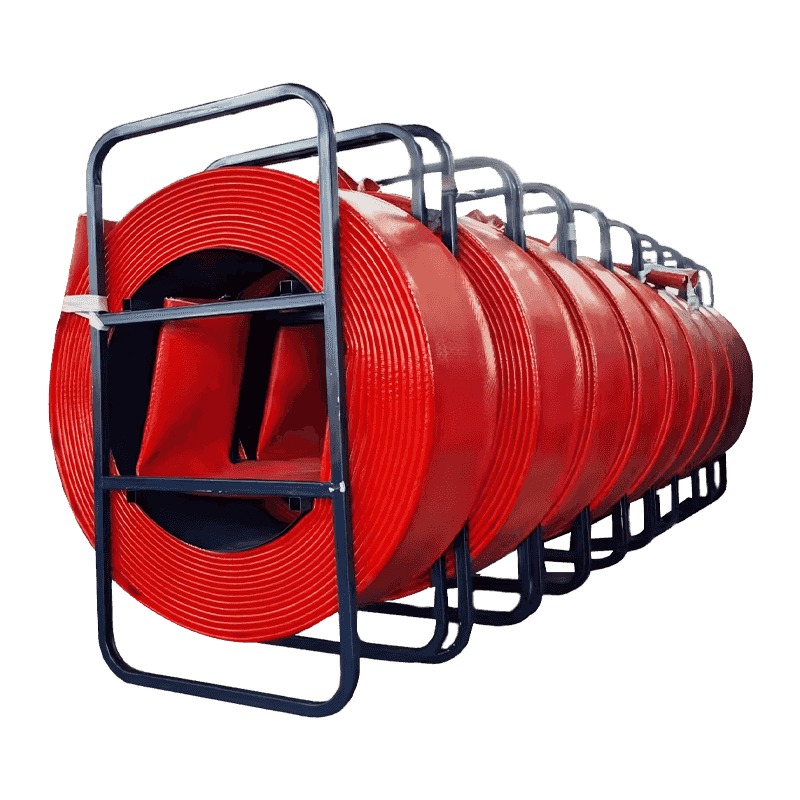

In industries such as oil and gas, mining, and agriculture, equipment durability is crucial, and the TPU Layflat Fracturing Hose is at the forefront of providing a reliable solution to meet the demanding needs of these sectors. Thermoplastic polyurethane (TPU) has gained significant traction in the production of fracturing hoses, thanks to its impressive resistance to harsh environments. Whether exposed to extreme temperatures, pressure, or aggressive chemicals, TPU-covered hoses deliver performance that outshines other materials, such as rubber and PVC. This innovative material ensures that fracturing hoses are up to the task in even the most challenging applications, making them an essential component in industries that cannot afford downtime or equipment failure.

The chemical resistance of TPU is one of the primary reasons why it is chosen for manufacturing fracturing hoses. This material stands strong when exposed to a wide variety of chemicals, including oils, fuels, and even some harsh industrial chemicals commonly used in the field. For example, the TPU layer covering the TPU Layflat Fracturing Hose acts as a protective barrier, preventing delamination or degradation that might otherwise occur with other materials like rubber. With TPU, industries involved in hydraulic fracturing or mining can rest assured that their hoses will maintain their integrity even under the most aggressive conditions.

Another significant advantage of TPU is its flexibility and ability to perform under high pressure. Fracturing hoses are often subjected to intense environments, especially during hydraulic fracturing in the oil and gas industry, where high-pressure fluids are pumped into the ground. The TPU construction ensures that these hoses remain pliable, preventing kinking or cracking while maintaining pressure integrity. This makes TPU-covered fracturing hoses ideal for long-term use, as they do not stiffen or lose their flexibility over time, which is a common issue with traditional rubber hoses.

In addition to its resistance to chemicals and pressure, TPU’s strength and durability make it a top choice for industries that require heavy-duty, long-lasting equipment. Fracturing hoses made from TPU are resistant to wear and abrasion, even when subjected to rough handling or exposure to sharp objects. This durability ensures that the hose will continue to perform efficiently throughout its service life, reducing maintenance costs and the need for frequent replacements. Companies in the oil and gas sector, as well as agriculture, will appreciate the cost-saving potential of these hoses, as they can significantly reduce downtime and the need for frequent repairs.

TPU also offers a lighter weight compared to other traditional materials like rubber, making the TPU Layflat Fracturing Hose easier to handle, transport, and install. This can be a major benefit when hoses need to be moved across large job sites or installed in remote areas where heavy equipment isn’t available. The lightweight nature of TPU hoses not only enhances efficiency but also reduces the strain on labor, making it easier for workers to install and manage hoses over long distances, especially in demanding environments.

As industries evolve and face increasingly complex challenges, the need for high-quality equipment becomes even more critical. Fracturing hoses made with TPU are engineered to meet these challenges, ensuring they stand the test of time. Whether it's the oil and gas industry requiring hoses that can withstand extreme pressures or the agricultural sector needing hoses for irrigation and chemical transfer, TPU offers unmatched durability and resistance. At Shenlong, we are committed to providing top-tier fracturing hoses that combine the latest material technology with industry expertise, offering solutions that businesses can rely on for years to come.

English

English русский

русский Español

Español Deutsch

Deutsch عربى

عربى Français

Français Português

Português